High polymer material perance test

In order to obtain better application of polymer materials, it is necessary to underst the composition, content certain physical chemical properties of polymer materials, it is necessary to conduct component analysis perance testing of polymer materials.

Rheological properties: melt mass/volume flow rate, mold shrinkage rate

Mechanical properties: tensile elastic modulus, tensile stress, tensile strain, tensile creep perance, bending modulus, bending strength, simply supported beam/cantilever beam impact strength, Shao Hardness, ball indentation hardness, Rockwell hardness, compressive strength

Thermal properties: melting temperature, glass transition temperature, load deation temperature, Vicat softening temperature, linear thermal expansion coefficient, combustibility, oxygen index, smoke density

Electrical properties: relative permittivity, dielectric loss factor, volume resistivity, surface resistivity, electrical strength, comparative tracking index

Other properties: water absorption, density, ash content, aging properties, etc.

| Test items | Test criteria |

| water absorption | GB/T 1034, ASTM D570, ISO 62 |

| Density< /td> | GB/T 1033, ISO 1183, DIN 53479 Method A, ASTM D792, |

| Ball compression hardness | GB/T 3398.1, ISO 2039.1, DIN 53456 |

| tensile strength | GB/T 1040,ISO 527,ASTM D638 |

| Tensile elongation at break | GB/T 1040,ISO 527,ASTM D638 |

| tensile modulus span> | GB/T 1040,ISO 527,ASTM D638 |

| tensile yield strength | GB/T 1040,ISO 527,ASTM D638 |

| Bending strength | GB/T 9341, ISO 178, ASTM D790 |

| Bending modulus | GB/T 9341,ISO 178, ASTM D790 |

| Compression strength | GB/T 1041, ISO 604, ASTM D695 |

| compression modulus | GB/T 1041, ISO 604, ASTM D695 |

| Cantilever impact | GB/T 1843, ISO 180, ASTM D256 (notched), ASTM D4812 (unnotched) |

| Simple beam impact span> | GB/T 1043, ISO 179, ASTM D6110 |

| ash content | GB/T 9345, ISO 3451, ASTM D5630 |

| compression permanent deation | ISO 815, ISO 7759, ASTM D395 |

| Aging resistance | GB/T 23987, GB /T 16422.2, ISO 4892-2, ISO11507,ASTM G 154,SAE J2020,

ASTM D 4459, ASTM G 155, GB/T 16422.3, ISO 4892-3 |

| humidity resistance< /td> | GB/T 2423.34, lEC 60068-2-38, EN 60068-2-38, ElA-364-31C |

| Shore hardness | GB/T 2411, GB /T 531.1, ISO 868, ASTM D2240 |

| melt index (weight method) | GB/T 3682, ISO 1133, ASTM D1238 |

| melt index (volume method) | GB/T 3682, ISO 1133, ASTM D1238 |

| Vicat softening point | GB/T 1633, ISO 306, ASTM D1525 |

| heat distortion temperature | GB/T 1634, ISO 75, ASTM D648 |

| Melting point< /td> | GB/T 16582, ISO 3146 |

| melting point DSC method | ISO 11357, ASTM D3418< /span> |

| Glass fiber content | GB/T 9345, ISO 3451, ASTM D5630 |

| Rubber hot air aging perance< /span> | GB/T 3512, ASTM D573, DIN 53508, JIS K 6257 |

| Xenon lamp aging | GB/T 1865, GB /T 16422.2, GB/T 2423.24,ISO 4892-2, EN 60068-2-5,IN ISO 11341, SAE J2412, ASTM D 4459,ASTM G 155 ,SAE J2527 |

Analysis of polymer material composition

Polymer material composition analysis has been wiy used in the field of commodity production, many domestic foreign companies use material analysis technology in their development research systems Watch track the latest research results development trends of the industry.

Plastics: Polyethylene (PE), Polypropylene (PP), Polyvinyl Fluoride (PVC), Polyethylene Styrene (PS), polyurethane (PU), polyamide (PA), polyoxymethylene (POM), polyphenylene sulfide (PPS), polycarbonate (PC), polymethylmethacrylate (PMMA), poly Ethylene phthalate (PET) etc.

Rubber: Neoprene (CR), natural rubber (NR), styrene butadiene rubber (SBR), Butyl rubber (IIR), nitrile rubber (NBR), ethylene propylene rubber (EPM), etc.

Paint analysis: Grease paint, natural resin paint, phenolic paint, asphalt paint, alkyd paint, amino paint , Nitrocellulose paint, over-curing vinyl paint, epoxy paint, etc.

Analysis of organic solvents: paint thinners, paint removers, cleaning agents solvents used in the electronics electrical industries, etc.

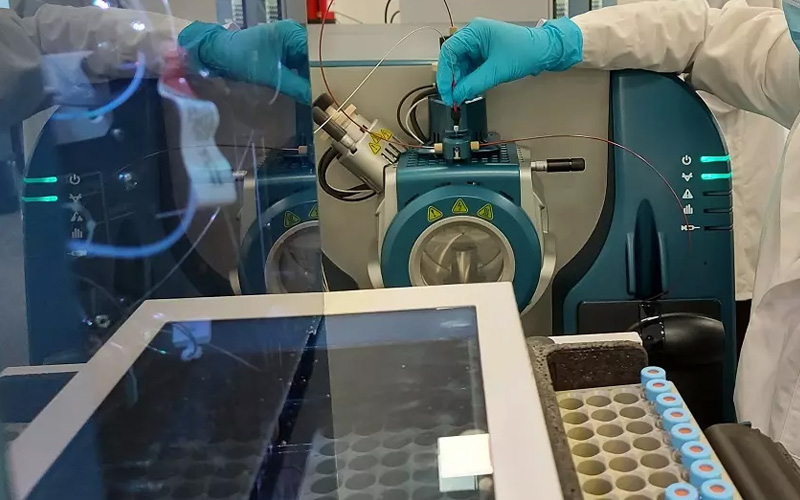

Common test methods instruments:

Dense Fourier Trans Infrared Spectrometer (FTIR)

Thermogravimetric Analyzer (TGA)

Pyrolysis/Gas Chromatography/Mass Spectrometry (PY-GC-MS)

Scanning electron microscope/X-ray energy spectrometer (SEM/EDS)

High Perance Liquid Chromatograph (HPLC)

Ultraviolet spectrophotometer (UV-Vis)